What make F1 Power Units so efficient? Let's dive into Turbulent Jet Ignition (TJI)

Here on Race Analysis we have often talked about the importance of aerodynamics in Formula 1, and how most of the design choices in the design of a single-seater are dictated by aerodynamic purposes.

However, in this turbo-hybrid era that Formula 1 is experiencing, the importance of the engine, or rather, as we are now accustomed to calling it, Power Unit certainly cannot be overlooked. The inspiring principle of the regulations in force since 2014 in Formula 1 was undoubtedly that of efficiency: the research and development on engines has therefore moved from trying to "simply" extract as much power as they can to trying to do it with a given amount of energy, available in the form of chemical energy present in the fuel and/or electrical energy from the battery pack (also known as "Energy Store", ES).

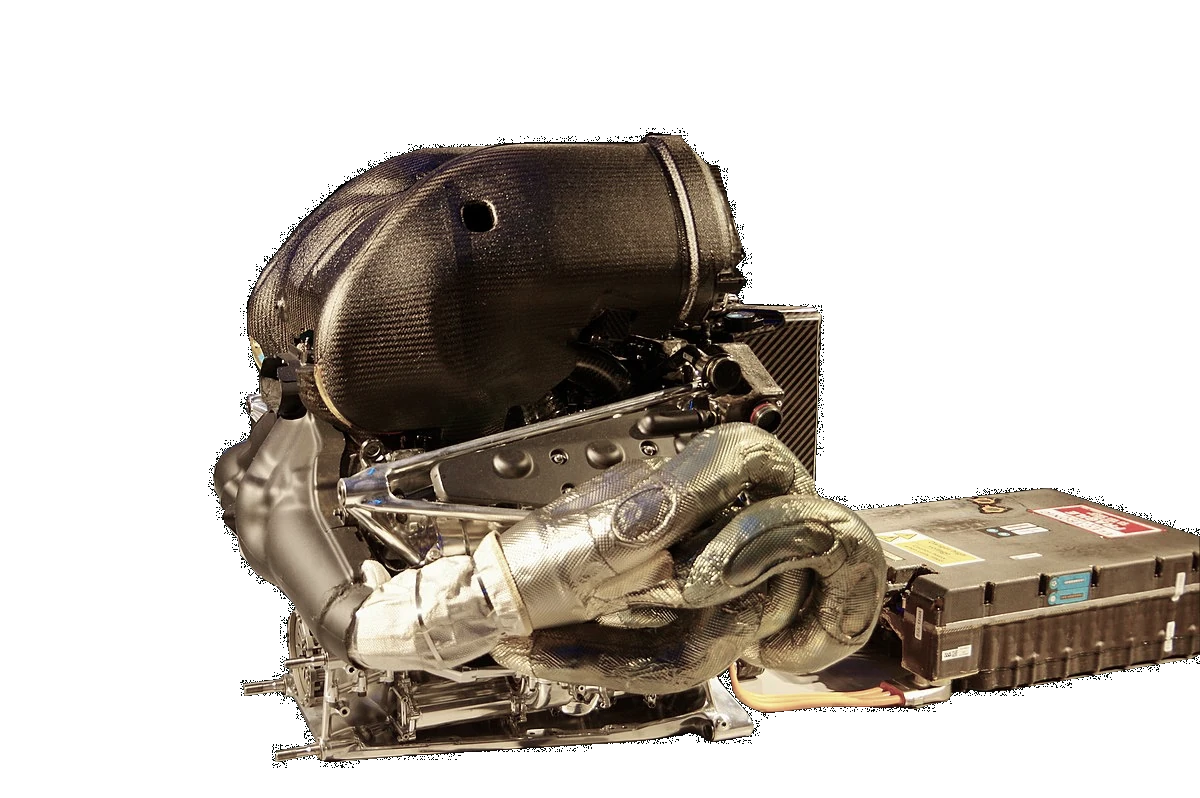

The Power Unit Mercedes used in 2014

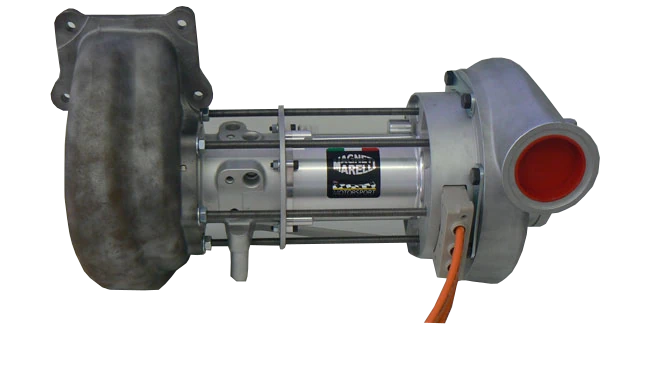

What was hiding behind this choice - not that it's stopped doing it! - was the desire to transfer the technologies that would have been acquired on the track to the automotive field, with the ultimate aim of providing greater sustainability to the fleets of vehicles that circulate on our roads every day. However, reality has confronted regulators with drawbacks that have made the current Technical Regulations less effective than intended: the main reason lies in the huge development costs of some technologies (the MGU-H above all, which in fact will no longer be featured in future Power Units starting from 2026).

Frame of a MGU-H (credit: Marelli Motorsport)

Therefore, if from a wider point of view the "transfer" to the automotive field has been decidedly less than desired, analyzing the developments from a purely scientific perspective, enormous technological progress has been made.

Cutting-edge technologies: “Turbulent Jet Ignition” (TJI)

The leading principle of efficiency has been pursued through two main limitations:

- A maximum load of fuel in the tank before the race, quantifiable in 110 kg;

- A limit on the maximum fuel flow, which increases linearly up to 10500 rpm and then remains constant at 100 kg/h beyond the above-mentioned engine speed;

It is immediately clear that if more power cannot be extracted from the internal combustion engine by increasing the fuel flow, the only possibility left is to waste the least possible quantity of energy contained in what we can inject: that's proper efficiency!

In fact, a major inefficiency that characterizes many internal combustion engines is linked to how much of the injected fuel is then actually burnt, and therefore participates in the process which - ultimately - supplies power to the wheels. The reason why some of the injected fuel is not combusted lies in the combustion chamber geometry and in the characteristics of the spray of air/fuel mixture.

With a normal direct injection, therefore, it would not be possible to have the level of efficiency needed to be at the top in Formula 1. That's why the German company Mahle (which works both in the automotive sector and in racing, where it has a close relationship with Ferrari) invented between 2014 and 2015 a system called "Turbulent Jet Ignition", abbreviated as TJI.

A TJI engine has the great advantage of using an air/fuel mixture that we define as "lean", i.e. containing a smaller quantity of fuel than the stoichiometric ratio, which instead would require about 14.65 kg of air for each kg of fuel. It goes without saying that using a lean mixture allows for greater flexibility, as:

- We can take on (and burn) the same amount of fuel as a non-TJI engine, obtaining more power for the same fuel consumption;

- We can take on less fuel than a non-TJI engine, obtaining the same power but with the advantage of having a lighter vehicle and lower fuel consumption;

This flexibility therefore translates into an immediate technical advantage over the competition, which in Formula 1 has appeared so clear that it has forced all Power Unit suppliers to buy or develop similar solutions for their engines. Nowadays, in 2023, Ferrari, Mercedes, Honda and Renault all run TJI engines.

But what makes the TJI engine use less fuel?

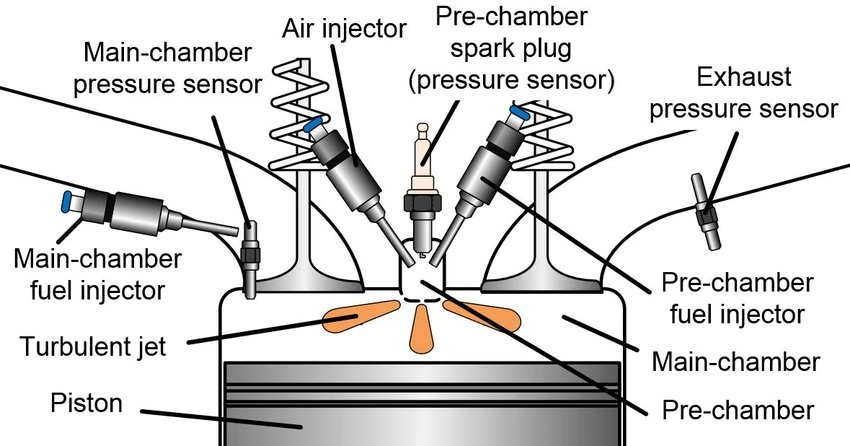

The typical geometry of the combustion chamber of a TJI engine features a "pre-chamber", the positioning of which is upstream of the main chamber, with which it is connected. The presence of the prechamber contains a small pocket of rich mixture (we are talking about 5% of the total mixture), therefore with a lower air/fuel ratio than the stoichiometric one - exactly the opposite of what was said before!

Architecture of a TJI engine (credit: Ruitao Song)

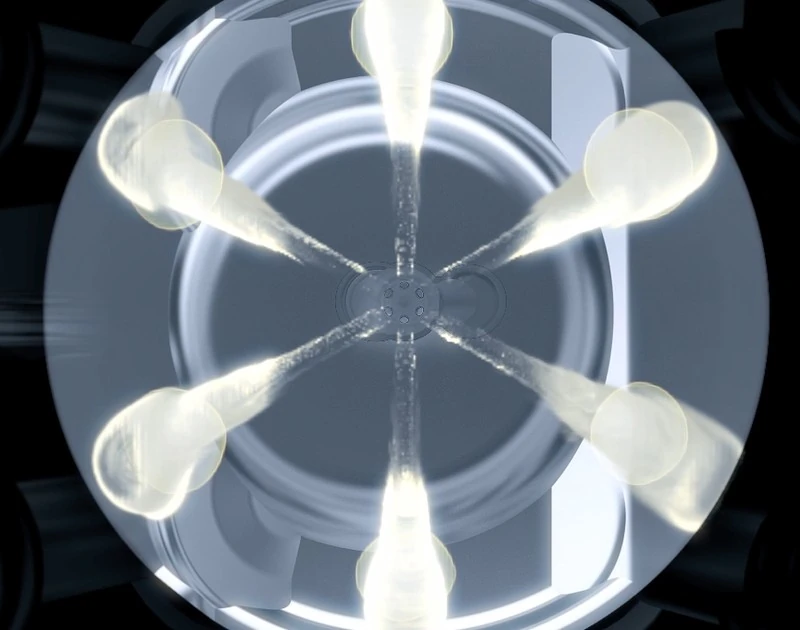

This small quantity of mixture in the pre-chamber is ignited by a spark plug, to then be sent to the main combustion chamber: when it reaches it, its motion field is strongly turbulent, and as is known, a turbulent motion helps the mixing inside the chamber. The transition of the mixture from pre-chamber to chamber takes place through a series of 6 or 8 small nozzles equally distributed on the external walls of the main chamber, and the advantage lies right here: having well-distributed points in which to accelerate the mixing of the air/fuel mixture avoids situations which normally occur in direct injection, i.e. with the volume near the injector which has a decidedly lower air/fuel ratio than the areas further away from it.

Nozzles for the injection from the pre-chamber (credit: MAHLE Powertrain)

At this point, you may be wondering when and how the remaining 95% of the mixture is injected, which will naturally be very lean. The moment of the injection is the one immediately following the aforementioned micro-injections, while the injection method is not unique.

In fact, we can have both direct injection (at high pressure) in the combustion chamber and indirect injection (at low pressure) in the intake port - using the intake stroke to draw the injected mixture into the chamber.

Respectively, these two injections are called:

- Gasoline Direct Injection (“GDI”);

- Port Fuel Injection (“PFI”);

When 95% lean and 5% rich mixtures are mixed, the overall air/fuel ratio is still greater than that of a non-TJI engine, with the associated advantage of having an absolutely more homogeneous flame front…

In this way, the probability that the entire quantity of fuel injected at each cycle is correctly burned increases, and with it the thermal efficiency of the engine.

What impact has TJI technology had on the automotive field?

A striking example of the application of Turbulent Jet Ignition to the automotive world is certainly the engine of the Maserati MC20, renamed "Nettuno" by the Trident engineers. It is understandable that the first vehicle to feature a TJI has been a sportscar, because in the design process of such vehicles the performance must be key; but we can bet that - net of the current trend to electrify the car fleets - if this technology were to see a reduction in its production costs, many car manufacturers would adopt it for their series productions. Triggering exactly that technological transfer that the FIA had in mind while writing the Technical Regulations for Formula 1.

Index

What make F1 Power Units so efficient? Let's dive into Turbulent Jet Ignition (TJI)